Facilities and Equipment

Nanolab

A Class 10,000 cleanroom with capabilities for micro and nano scale measurement.

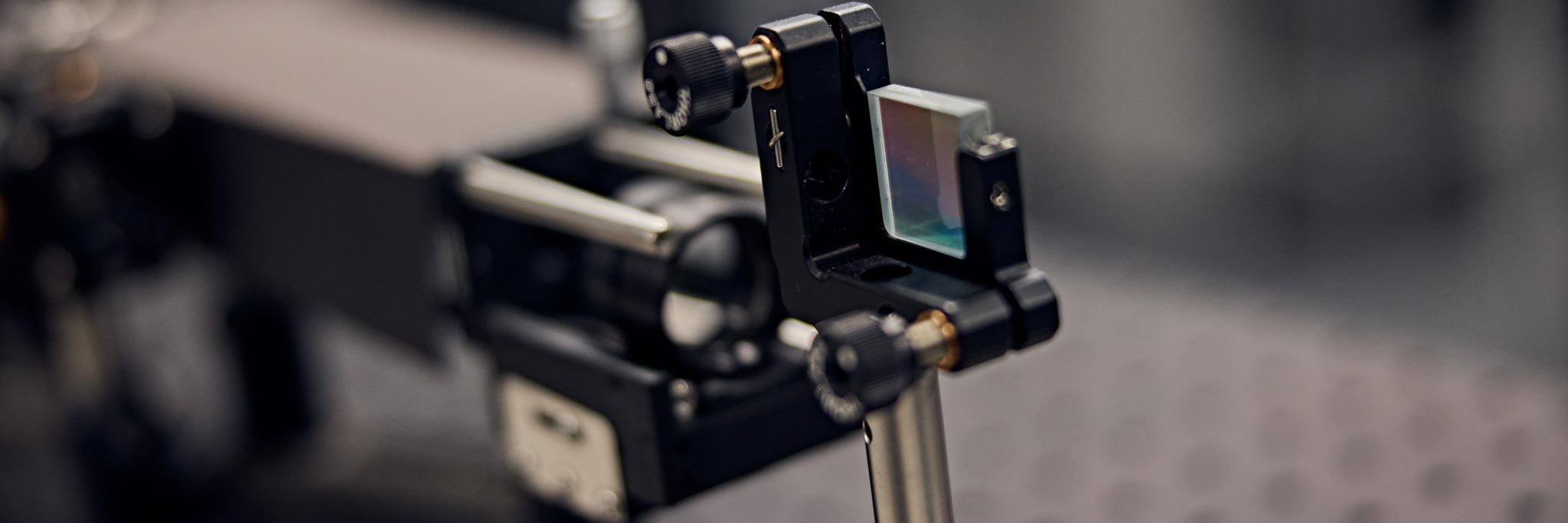

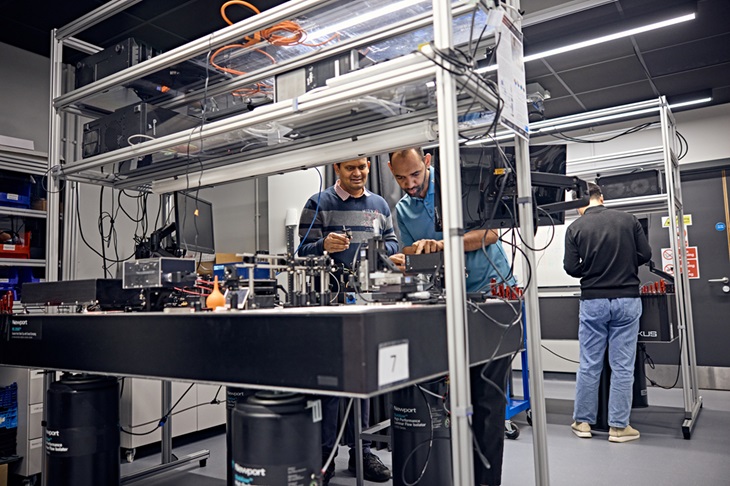

Optical Instrumentation Lab

A state-of-the-art lab used in developing new optical measurement instruments.

Ultra-precision Machining Lab

Housing two Ultra-precision machining centres for diamond turning and micro-grinding and milling.

Machine Tool & Robotics Lab

Our machining & robotics lab is well equipped with a variety of equipment available to our researchers.

Metrology & Calibration Lab

Our metrology lab is perfectly equipped for characterising both components (CMMs) and machine performance (calibrators).

The Nanolab facility is built around a temperature controlled, class 10,000 clean room with several damped measurement stations capable of isolating equipment from background noise. The lab is primarily used for surface measurement and characterisation but has flexible spaces which can be used for other commercial or research measurement.

Key Equipment:

- Nikon XTH 225 micro CT machine

- Alicona infinite focus microscope G4 rotary stage

- Keyence VHX digital microscope VHX-500F

- 20 – 200 magnification and 500 – 5,000 magnification

- Taylor Hobson precision Talyrond 365

- Alicona infinite focus microscope G5

- Bruker Contour LS focus variation system

- Taylor Hobson form Talysurf PGI contact profilometer

- Taylor Hobson Talysurf CCI white light interferometer

- Bruker Dektak ultra-low force contact profilometer

The Ultra-precision machining lab houses the group’s two ultra-precision machining centres, each with its own dedicated temperature-controlled room, clean air supply and workspace for experiments.

Key Equipment:

- Precitech Nanoform 250, 3-axis diamond turning machine, with a Nakanishi grinding spindle, in-house developed on-machine metrology and fast-tool-servo systems

- Moore Nanotech 650 FG V2, 5-axis diamond turning machine, with a 6 mm range fast-tool-servo, a 60K grinding spindle, and in-house developed on-machine metrology system

- IPG 30W nanosecond laser with galvo scanner

- Taylor Hobson TalySurf surface profilometer

- FISBA OPTIK FS10 interferometer

- Precitec chromatic confocal probe

In 2023, the University invested over £800k in the creation of a new 250m2 state-of-the-art optical lab with core equipment including: advanced fringe projection profilometry systems, white-light interferometers, and dedicated space for new instrument development. The lab is equipped with isolated work stations and has comprehensive laser safety facilities.

Key Equipment

- Arinna white light scanning interferometer

- High-speed fringe projection (1000 Hz) toolkit

- Stereo deflectometry toolkit

- High precision deflectometry configurable toolkit

- Ocean optics Flame – T spectrometer (780-920 nm)

Thorlabs CCS 100 spectrometer (300-700 nm)

Thorlabs optical spectrum analyser OSA 201C (350-110 nm)

- Solar laser systems S150

- Lightsources

- White lace supercontinuum laser

- Exalos SLEDs, 1-5 mW, 780-850 central wavelength

- Various tuneable lasers and laser diode sources

- Pulsed laser

- Motion Control

- Newport linear stepper stages – range 25mm, resolution 0.1um

- PI PZT precision linear stages – ranges 100-500, µm, resolution 1 nm

- 4 axis Aerotec motion stage

- High performance parallel computing hardware

5 x high-performance vibration isolation optics benches

Beam analysis toolkit

Our metrology lab is perfectly equipped for characterising both components (CMMs) and machine performance (calibrators). We have all CMM methodologies at our disposal (touch-trigger, scanning & optical), depending on the research requirements. We are also skilled practitioners in machine tool calibration & error measurement, collaborating with key industry partners over the years to help them calibrate their machines for optimal performance. Some key examples of our metrology toolset can be found below:

CMMs

Zeiss Prismo Access CMM - The ZEISS PRISMO Access is a high-precision coordinate measuring machine (CMM) designed for both quality labs and production environments. It is notable for its high accuracy and speed, capable of dynamic 3D scanning and automatic correction for probe radius.

Renishaw Equator gauging system - The Renishaw Equator is a flexible, high-speed and thermally insensitive comparison gauge system designed for shop-floor use in medium-to-high-volume manufacturing. The system uses a comparative gauging method, comparing production parts to a master part, and can be reprogrammed to adapt to different parts.

Baty Venture Plus Optical CMM - The Baty Venture Plus is a multi-sensor optical system for the precise, automated measurement of large workpieces, combining non-contact optical measurements with optional touch probe capabilities. It has a large measuring range, air-bearing axes, a granite Y-beam for accuracy, and advanced software with video edge detection.

Calibration & Positional /Error Measurement

Renishaw XM-60 - The Renishaw XM-60 is a multi-axis laser calibrator that measures all six degrees of freedom (6DoF) of a linear axis simultaneously, including linear, pitch, yaw, roll, and straightness errors. It provides a fast way to diagnose and correct machine tool and motion system errors and creates a detailed spatial accuracy map of the machine.

Renishaw XL-80 - The Renishaw XL-80 is an ultra-stable laser interferometer system used to calibrate and measure the performance of machine tools, CMMs, and motion systems. It provides highly accurate and traceable linear, angular, and straightness measurements by establishing a stable, traceable laser beam.

Renishaw Ballbar - A Renishaw Ballbar is a precision telescopic sensor used to characterise the geometric and positioning accuracy of CNC machine tools by monitoring deviations from a perfect circular path. It is magnetically mounted between the machine's spindle and bed and collects the data as the machine moves in a circular program to identify and quantify issues like backlash, stick-slip, and geometric errors.

Hexagon laser Tracker - The Hexagon laser tracker is a high-precision, portable 3D metrology device that uses a laser beam to measure the coordinates of points on large objects or within complex assemblies.

Our machine tool & industrial robotics lab is well equipped with a variety of equipment available to our researchers, and for collaborations with industry and academia. The Group has extensive experience with both traditional and innovative CNC machine tools, as well as using serial & parallel kinematic industrial robots for manufacturing applications. In total, we have nearly 40 examples of specialist equipment deployed for research (including CNC machine tools, robots, CMMs & calibration/positional tracking).

The purpose-built Advanced Manufacturing Laboratory opened in March 2022 providing 500 square metres of manufacturing / research workshop and lab space, housing five 3- and 5-axis machine tools along with industrial robots, and test facilities for components of machinery. Our coordinate metrology equipment is housed in a dedicated temperature-controlled measurement facility

With its prominent position within the university’s central plaza, the facility gives our team and partners a well-equipped, flexible environment to conduct their research and industry projects.

Traditional 4/5 axis CNC Machines

Our research covers a variety of CNC machine tools and types from different manufacturers. We regularly devise and conduct testing to investigate the fundamental mechanisms governing machine tool performance and machining processes. Specifically, our work examines surface texture formation, tool wear, drive system degradation, heat generation, and geometric error accumulation caused by the machine and its environment, including the complex issue of thermal errors.

To support this research, we have designed and deployed embedded sensing systems capable of monitoring acceleration, system temperature, and acoustic energy. In addition, we proactively integrate cutting-edge technologies to enhance both research efficiency and measurement precision. These technologies include, but are not limited to, large-scale data management platforms, multi-modal modelling using deep learning techniques, and a knowledge twin framework that leverages a self-hosted graphical presentation engine alongside factory-level streaming data transmission protocols.

Some examples of the CNC machines we use can be found below. This list is not exhaustive, and we frequently work with many industrial and academic partners which provides access to equipment and expertise beyond our own facilities. Please contact us if you have any specific queries or interests.

CNC Machines

Cincinnati 2 Arrow 2-500 - 3-axis vertical CNC machine built by Cincinnati Milacron. Specific work envelope dimensions are X and Y-axis travel of 600mm and a Z-axis travel of 600m, coupled with a Siemens 840d controller.

Hurco VXM 30ui - 5-axis vertical CNC machine. It includes an integrated trunnion table, a 12,000 rpm spindle, a versatile Hurco WinMax control unit for simplified programming, and a robust build for stability.

Geiss CNC - A large volume, Head-Head, 5-axis CNC milling machine in a gantry configuration, coupled with a Siemens 840d controller.

FANUC robodrill Alpha T14iDE - Compact, 3-axis, high-speed vertical CNC machine. It features a BT30 spindle taper and a 14-tool automatic turret (ATC).

Robotics for Machining

The Group carries out modelling of industrial serial and parallel kinematic robots, which is required for improving the precision of robots in their use as machine tools as well as building more accurate digital twins of machining processes. It also helps formulate calibration strategies in small and large volume metrology setups. Some examples of our robotic capability can be found below:

Robots

Kuka - The KUKA KR 210 is a robust, 6-axis industrial robot with a high payload capacity of 210 kg, designed for heavy-duty, high-performance tasks like heavy part handling, machining, welding, and palletizing.

Exechon X Mini - The Exechon X-Mini, developed by Exechon LLC and built by our friends at the Advanced Manufacturing Research Centre (AMRC) in Sheffield, is a state-of-the-art, parallel kinematic machine tool robot (PKM Robot). It combines the high dynamics and flexibility of an articulated robot with the rigidity and accuracy of a traditional machine tool; and is the first example of a carbon fibre machine tool robot.

FANUC Robot Arm R-1000𝑖A/80F - The R-1000𝑖A/80F is a 6-axis robot arm designed for handling 80Kg payloads at high speeds. It achieves efficient cycle times in operations such as welding, handling, and palletising.