Research Areas

Our Research

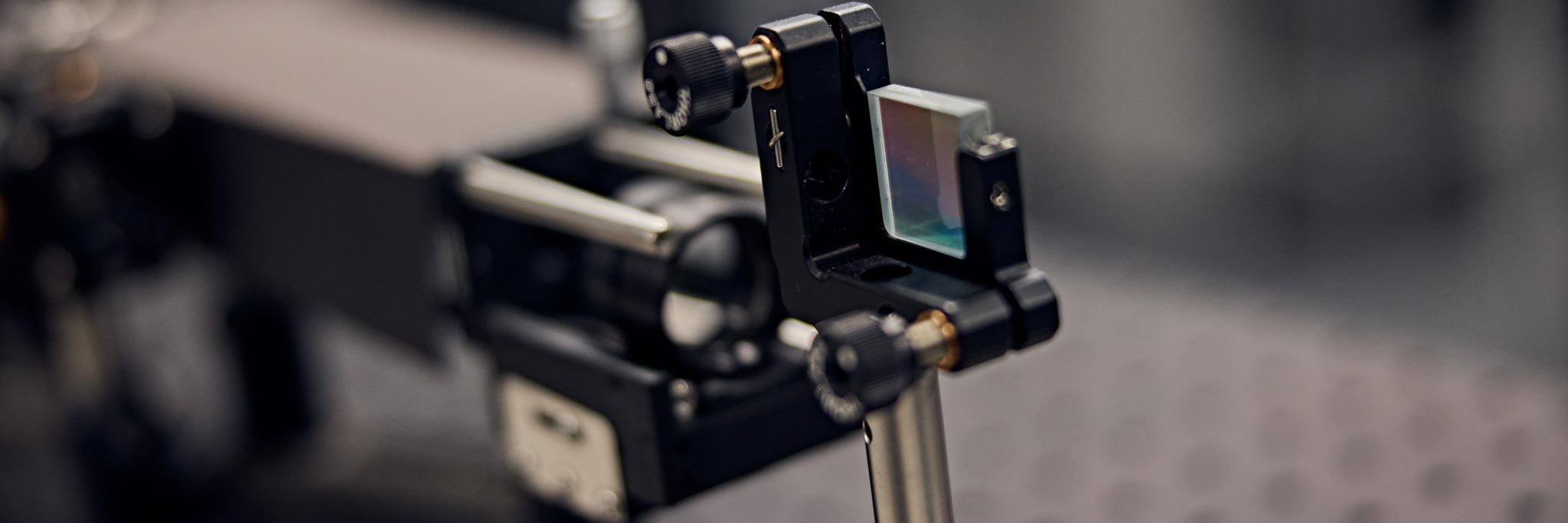

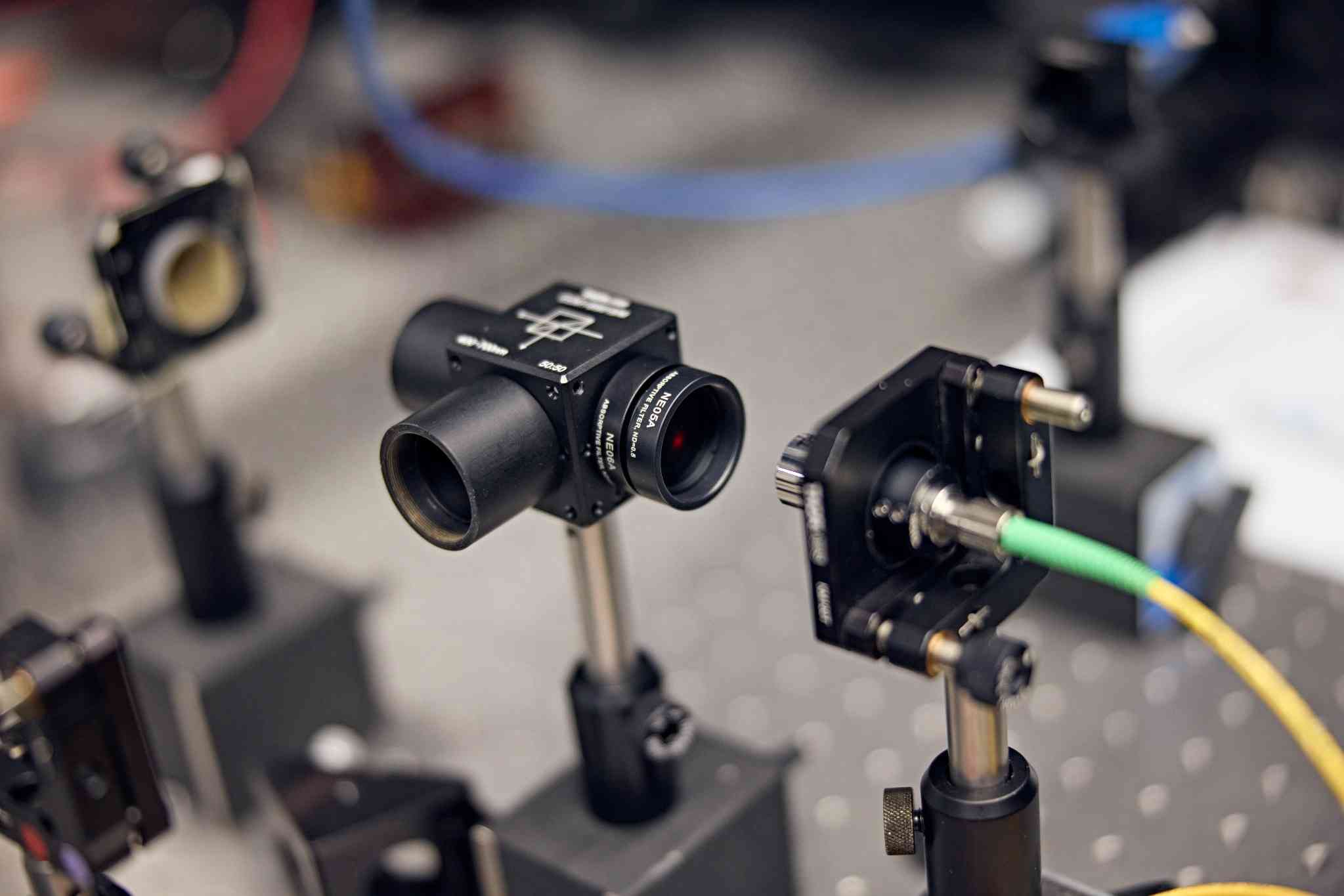

Optical Instrumentation

Optical metrology uses light to measure distance, shape, and surface texture in manufacturing. It offers fast, non-contact, high-resolution measurement. At CPT, researchers are developing new optical technologies and physics to create compact, powerful instruments for in-situ use.

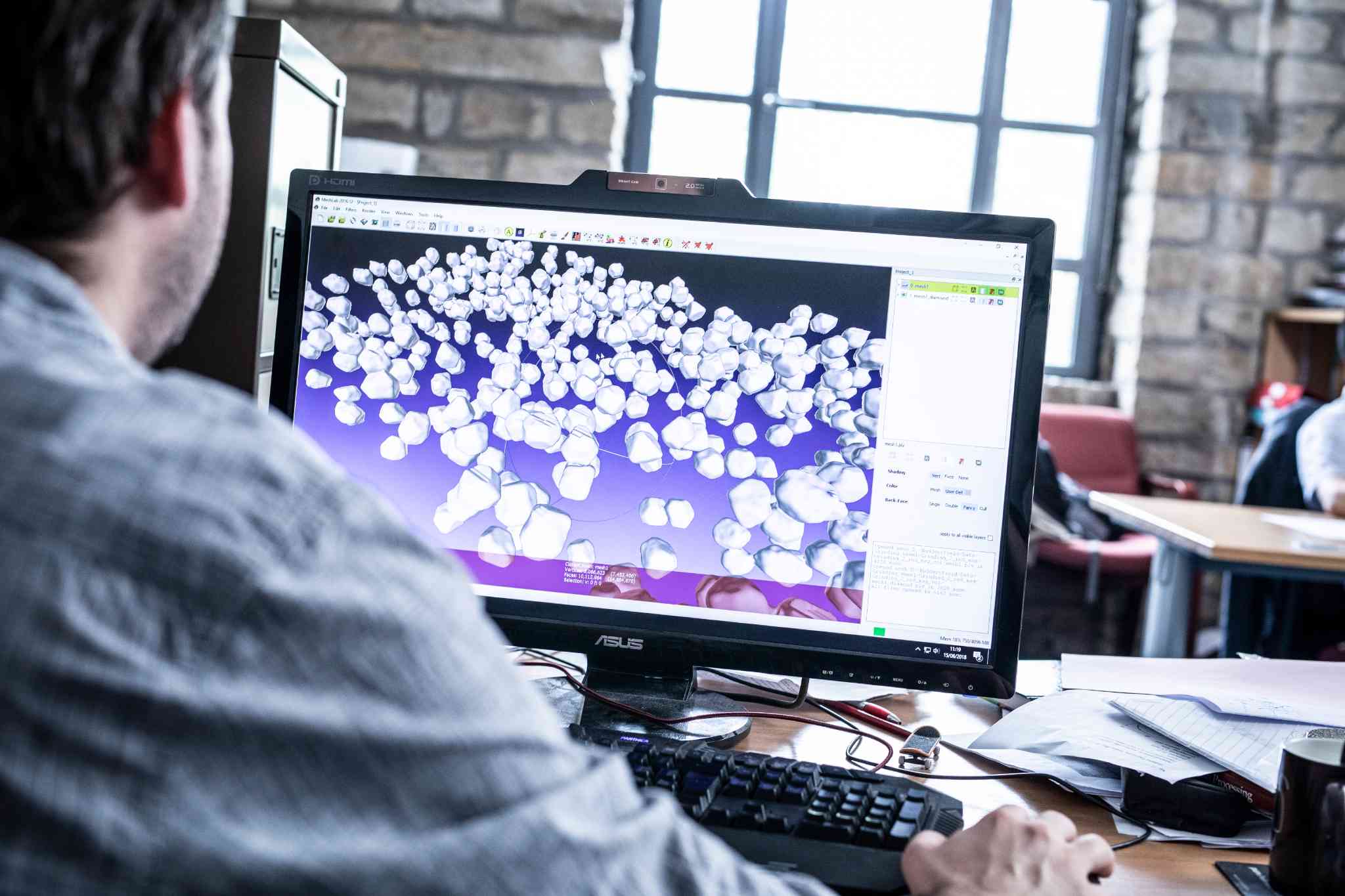

Surface Metrology and Applications

CPT provides advanced surface measurement for research and industry, using both contact and non-contact systems, modelling, replication, and XCT. Applications range from aerospace to bio-implants, and from ultra-smooth to additively manufactured rough surfaces.

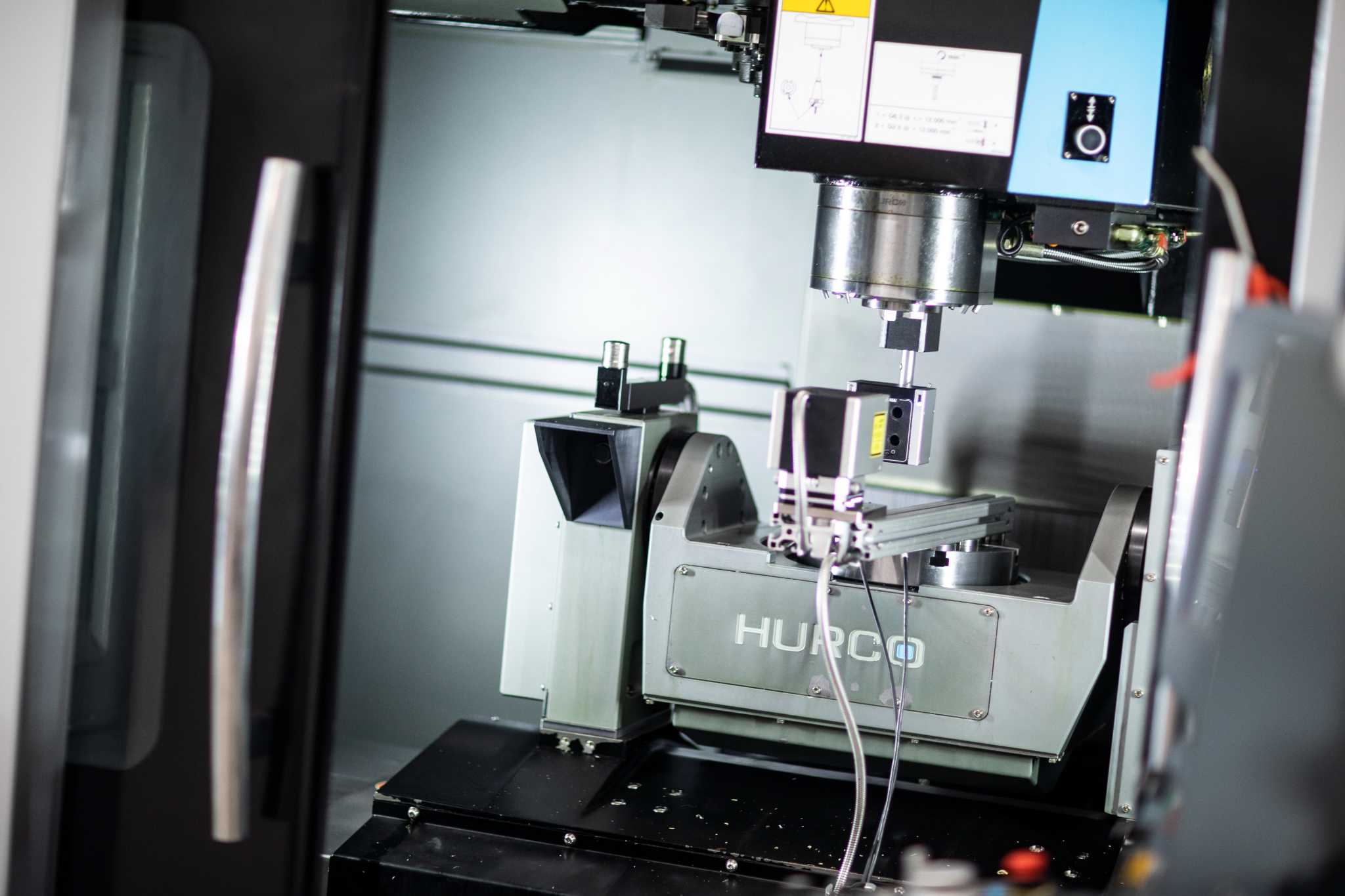

Ultra-precision Manufacturing

CPT operates cutting-edge machining centres for diamond turning, grinding, and tool servo control, enabling production of components with ultra-fine surfaces and micro/nano-scale features.

Mathematics for Metrology

CPT develops computational methods to process vast amounts of metrology data in real time, advancing mathematical languages, standards, and data handling techniques to support modern manufacturing.

Performance Assessment of Manufacturing Machinery

CPT are experts in evaluating manufacturing machinery, addressing errors, uncertainties and calibration across machine tools, robots and dimensional metrology systems like CMMs.

Advanced Compensation of the Errors of Machines

CPT investigates geometric and thermal error correction in machine tools, using advanced techniques like AI-driven prediction and real-time compensation to enhance accuracy and productivity.

Machine Learning to Improve Machine Performance

CPT develops validated ML algorithms for error detection, predictive maintenance, and process optimisation. Focus areas include interoperability, allowing ML solutions to work across diverse machines and systems.

Metrology for Performance and Product Verification

CPT reduces product verification costs by creating in-situ sensing and monitoring systems. Their Smart Workshop project continuously tracks parameters like temperature, vibration, and coolant quality to improve tool performance and industry ROI.

Design of Machinery and Control Software

CPT uses high-fidelity digital twins to de-risk investment in manufacturing, enabling design, testing, and control in the virtual domain before costly assets are purchased or commissioned.

Extended Reality (XR) for Advanced Machinery

CPT explores VR, AR, and MR to enhance product development, quality control, and workforce training. XR applications also support virtual testing, hazard identification, workflow optimisation, and remote collaboration.