Porous ceramics and composites – from processing to simulation

Wednesday, April 10th 2019

Sparck Jones Building SJG/11

11:15

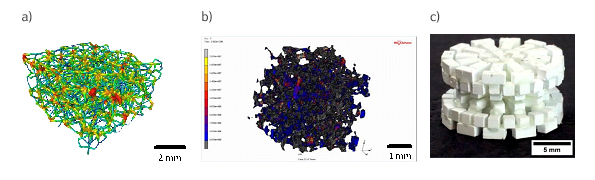

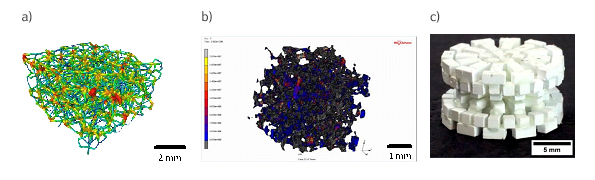

Abstract. Cellular materials offer a wide spectrum of applications such as catalyst support structures, lightweight materials, energy adsorption or energy storage materials. Due to several ways of processing and different materials, a wide range of material properties e.g. thermal conductivity, mechanical strength or damping can be adjusted, measured and verified, with regard to the expected properties. Various techniques for processing porous ceramics and composites independent of material are presented. Especially in heterogeneous and homogeneous porous structures and their composites, only global effective material properties can be determined and measured. Knowledge on the predominating influence of the microstructure on the global properties is the key for designing materials with desired properties. To fill this gap and enable a "look-in" a model of microstructure derived from µCT measurements carried out at certain processing steps can be used as model for FEM-calculations. Combining estimated material properties by experiment with models of microstructure offers the possibility to carry out different simulations over different hierarchical levels. In contrast to experiments, also the pore network or the composite network and their influence on global parameters can be analysed. This approach is carried out on different cellular structures and composites (see Figure 1).

Figure 1: a) Pore network of a 30ppi replica foam, b) FEM-simulation of stress distribution in a MAX-phase gelcasted foam, and c) scaffold of hydroxyapatite building blocks and epoxy resin for block fixation.

All welcome to attend

Enquiries to v.vishnyakov@hud.ac.uk

Latest references:

Stumpf, M., Fan, X., Biggemann, J., Greil, P., Fey, T. Topological interlocking and damage mechanisms in periodic Ti2AlC-Al building block composites, Journal of the European Ceramic Society (2019) 39(6), pp. 20032009, https://doi.org/10.1016/j.jeurceramsoc.2019.01.047

Biggemann, J., Pezoldt, M., Stumpf, M., Greil, P., Fey, T. Modular ceramic scaffolds for individual implants, Acta Biomaterialia 80 (2018) 390–400, https://doi.org/10.1016/j.actbio.2018.09.008

Fey, T., Stumpf, M., Chmielarz, A., Colombo, P., Greil, P., Potoczek, M. Microstructure, thermal conductivity and simulation of elastic modulus of MAX-phase (Ti2AlC) gel-cast foams , Journal of European Ceramic Society 38 (10) (2018) 3424-3432, https://doi.org/10.1016/j.jeurceramsoc.2018.04.012

Biggemann, J., Diepold, B., Pezoldt, M., Stumpf, M., Greil, P., Fey, T. Automated 3D assembly of periodic alumina-epoxy composite structures, Journal of American Ceramic Society 101 (10) (2018) 3864-3873 https://doi.org/10.1111/jace.15586