WOVEN in Practice - Speakers Day 2

Saturday 24 April 2021

Innovative Textiles

Ashleigh Naysmith

PhD Research, Technical Textiles Research Centre, Uni of Huddersfield

You won't see the light if you don't feel the heat: Smart textiles for thermoregulation

Cassie Quinn and Oonagh O'Hagan

CQ Studios, Central Saint Martins and University of the Arts London

Fashion: An Alternative Future

Anna Watkins

Department of Fashion and Textiles, Uni of Huddersfield and Uncommon Alchemy

Seaweed, Slime and Mad Science: A Love Letter to Biomaterials

Ecological & environmental approaches I

Olufemi Adetunji

Doctoral Researcher, University of Newcastle, Australia

Textile Making in Changing Climate in South-Western Nigeria

Charles Ross

Royal College of Art

ReGenerative Agriculture - How natural ingredient sourcing can create a climate positive garment

Dr Hafsa Jamshaid

Associate Professor, National Textile University, Faisalabad

Sustainable Products

Ecological & environmental approaches II

Vicky Price

The potential for sustainable use of waste digital print products into hand crafted textile prints

Technological innovations

Dr Kevin Almond

Lecturer in Fashion, University of Leeds

Pedagogical and Educational Practices in Fashion and Textiles: The Serendipity of Manufacturing Mistakes

Claire Evans

Senior Lecturer, Department of Fashion and Textiles, Uni of Huddersfield

Exploring grainline tilt through virtual garments wearer trials

Ashleigh Naysmith

PhD Research, Technical Textiles Research Centre, Department of Fashion & Textiles, University of Huddersfield

You won't see the light if you don’t feel the heat: Smart textiles for thermoregulation

Ashleigh is a PhD researcher in materials science working on the development of thermoregulation in e-textiles for the Technical Textile Research Centre at the University of Huddersfield.

Her passion is in materials and how their design can affect human behaviour; she has a keen interest in blending design thinking with scientific research to add new perspectives to the way we create. She combines this with a love of the outdoors and Going Nice Places, Doing Good Things.

Humans are warm-blooded creatures, so thermoregulation is a tale as old as time. In today’s world, the human need for maintaining a constant temperature underlies key environmental, socioeconomic and medical challenges, alongside daily discomforts. This presentation will discuss how the emergence of thermoregulatory smart textiles has the potential to address some of these challenges and how transdisciplinary collaboration can facilitate commercially viable developments starting from innovation to consumer use.

Cassie Quinn

CQ Studio and student on MA Biodesign at Central Saint Martins.

Oonagh O'Hagan

University of the Arts London

Fashion: An Alternative Future

Oonagh O’Hagan is a graduate of the MA in Fashion at St Martins, where she now lectures in addition to working as a freelance designer and art director. She presently is studying part-time for a PhD in relation to design, desire and the impact of technology.

Cassie is a student on MA Biodesign at Central Saint Martins. Her work is placed at the intersection of fashion and science, questioning material permanence and how we can collaborate outside of fashion to build more environmentally considerate practices.

The presentation is situated between themes of ‘The social, ethical and aesthetic dimensions to practice in fashion and textile contexts’ and ‘Technological innovations in fashion and textile practices’. They aim to highlight the importance speculation has in the context of fashion through investigating innovations in textiles and exploring how they can play a role in widening our scope of aspiration. Applying Oonagh’s speculative design vision to Cassie’s materials they propose a thought-provoking world where our textiles are grown as dual-crops, providing a food source as well as clothing for our bodies.

Anna Watkins

Department of Fashion & Textiles, University of Huddersfield & Uncommon Alchemy

Seaweed, Slime and Mad Science: A Love Letter to Biomaterials

Anna Watkins is the founder of Uncommon Alchemy, a sustainable materials development studio working on new materials for use in fashion and lifestyle products. She has a particular interest in biomaterials, working primarily with seaweed and industrial waste streams to transform them into exciting new materials.

Anna describes her journey to discovering the weird and wonderful world of biomaterials, and how she has gone on to develop this practice into sustainable materials for fashion. She talks through the joys (and the challenges) of working at the intersection of nature, science, and craft to develop new materials that can offer a better alternative for people and the planet, without sacrificing style or self-expression.

Olufemi Adetunji

Doctoral Researcher, School of Architecture and Built Environment, University of Newcastle, Australia

Textile Making in Changing Climate in South-Western Nigeria

Olufemi Adetunji is an academic at University of Newcastle, Australia where he is conducting practice research. He is also involved in engaging communities and cultural/creative organisations in leveraging culture, art and heritage for sustainable development of communities.

Within South-Western Nigeria, various communities are involved in adire, batik, woven, ankara and several other traditional textile making technologies. Communities such as Abeokuta, Oyo, Osogbo and Ado-Ekiti are known for ankara, adire and woven textile making, using of materials and equipment that a sourced from the local resources such as dye, local cotton etc. However, many of the local resources are depleting due to changes in rainfall pattern, temperature, depletion of local sources of water and other impacts of climate change. In Abeokuta, for instance, many of the textile weavers have abandoned making adire due to depletion in raw materials such as cotton, dye and water.

This discourse seeks to examine the impacts of the changes in climate on traditional textile making in communities across South-Western Nigeria and develop strategies to adapt to the impacts in view to conserve the indigenous knowledge and practice involved in traditional textile making.

Charles Ross

Royal College of Art

ReGenerative Agriculture - How natural ingredient sourcing can create a climate positive garment

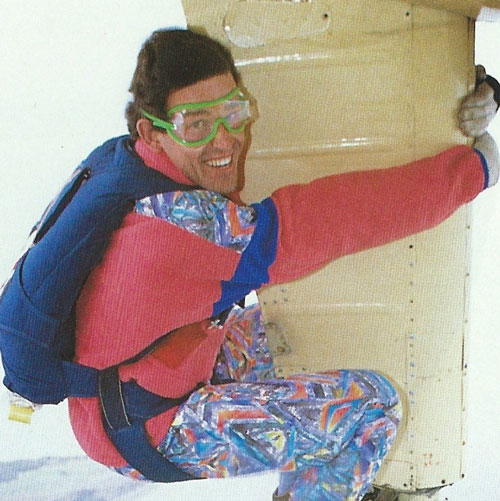

Charles Ross has taught Performance Sportswear Design for over two decades, now he is staff at the Royal College of Art. However most of his work is at Outdoor companies who are trying to implement better practice whether in terms of materials or processes. He sits on Wrap textiles, is a Design Council mentor, does work with Innovate UK, lectures in Europe, North America, & Asia, plus writes columns for various international & local publications centred on the theme of Sustainability through Longevity. His best work is the graduates he has focused.

ReGenerative Agriculture is becoming a buzzword with several Outdoor brands: Patagonia are using this type of cotton, Finisterre are sourcing the wool, Timberland – the leather, whilst The North Face have already launched products using this wool, but are currently integrating the cotton within their supply chain. The trend all this Millennium has been to reduce the footprint of products – could this be the tipping point to change?

Dr Hafsa Jamshaid

Associate Professor, National Textile University, Faisalabad

Sustainable Products

Dr. Hafsa Jamshaid is working as Associate Professor at National Textile University. She is an experienced textile professional in the field of weaving, knitting technologies for technical fabrics and composites. Her textile engineering education is from Technical University of Liberec and University of Engineering and Technology, Lahore. Her area of expertise is structures, composites, comfort and recycling.

Nowadays, the world faces unprecedented challenges in social, environmental and economic dimensions, in which the industrial design has showed an important contribution with solutions that provide positive answers regarding these problems. The major portion of fibres goes to the textile industry whose main output streams are apparel and home textiles. With the transformation of these textile products from a basic human need to fashion items, their lifetime before disposal is steadily declining, while at the same time the complexity of their material composition is increasing. The amount of disposed items is increasing and the issue of a proper handling of end-of-life textiles is becoming more important. Present technological development and innovation needs a better class of material that meets all the practical applications along with its environmentally friendly nature and economical value. The topic of this talk is the use of environmentally friendly materials especially Basalt and development of value-added woven products from recycled materials.

Dr John G Parkinson

iinouiio Co-founder/Director

Recycling our past; creating a future

The first large-scale textiles circular economy began in Batley, Yorkshire around 1813. For two-hundred years, the shoddy and mungo trade revolutionised woollen spinning practices, transforming waste textiles into new material that reached across the world. After WWII, the industry contracted, largely due to changes in fashion and oversees competition. Nevertheless, John Parkinson, joined his father’s small recycling business in 1977 and by 1990 John established ‘Evergreen’ to develop recycled fibres by incorporating other ‘responsible’ materials and production methods to create yarns and fabrics. Evergreen was the first business of its kind in the UK, long before terms such as ‘fast fashion, circular economies and sustainable textiles were in common use. Devastatingly, in 1995, a fire destroyed the factory forcing its closure. However, the heritage, beauty and craft of textile recycling proved irresistible and (against the odds) in 2020 John’s new business ‘iinouiio’ (acronym: ‘it is never over until it is over’) launched the first UK recycled wool collection of its kind since Evergreen. As of January 2021, iinouiio plans to re-establish a recycling facility to recover wool textiles, employing traditional practices both for their own brand and to help textile manufacturers manage their waste more effectively and open-up emerging markets.

The purpose of iinouio’s involvement in the WOVEN conference 2021 is to join with FFF and UoH to reveal the progress to date and answer questions about this craft.

Rachel Clowes

The Sustainable Sequin Company

Rachel is an experienced sustainable textiles researcher, technician, educator and designer. She is the founder of The Sustainable Sequin Company and is working to create bio-based, biodegradable sequins.

Synopsis

Mainstream fashion has, up until very recently, failed to consider the appropriate durability of its decoration. Plastic sequins shimmer for a few hours on the dance floor before lying intact in landfill for a few centuries or more. The raw materials from which sequins are derived and the waste created by short-term use of long-lasting plastic are environmental concerns. Rachel, from The Sustainable Sequin Company, talks about the ongoing journey to create more sustainable sequins for the fashion industry.

Vicky Price

The potential for sustainable use of waste digital print products into hand crafted textile prints

Vicky Price is working freelance within practice-based research into textile print, the ecological and innovative use of waste digital print dyes and end-roll fabrics, increasing the authenticity of textile design with site-specific technical crafting, including drawing in a three-dimensional world. Ecological and environmental approaches to fashion and textiles making and building a hand-crafted collective vision for future print development have been the main factors for the research, as have her technical print application knowledge and imaging of cloth and fibres. Her dedication to printed textiles has recently initiated her company Studio Colourphilia, as a designer intent on creating innovation in the mainstream textile market for interiors, architectural installation, theatre and fashion, aiming to make the textile as important as the garment and as significant as the interior that the textile dresses.

Currently funded by the Society of Dyers and Colourists and the Worshipful Company of Dyers studying one-year Foundation Colour Chemistry, this presentation showcases unpublished research based on utilising recovered waste digital inks and colour science, where the newly developed process of screen print and hand applied print allowed a system of experimentation which meant I was no longer confined to a studio space. Working on location making in response to the environment, direct to fabric, brought an authenticity of marks, not contrived nor enhanced digitally. Large scale fabrics were in their raw state and innovative pieces went into studio design, creating additional research into print resists from non-textile ingredients.

Dr Kevin Almond

Lecturer in Fashion, University of Leeds

Pedagogical and Educational Practices in Fashion and Textiles: The Serendipity of Manufacturing Mistakes

The research describes a case study that asked fashion design students to identify mistakes in manufacture, in selected garments from the Yorkshire Fashion Archive held at University of Leeds. It explored the potential for accidental or intentional mistakes to be a source of inspiration for fashion design. There is a lack of literature that describes how fashion designers have been inspired by manufacturing mistakes in archive garments, which the research sought to redress. A broader literature review emphasized how definitions of human mistakes have stimulated ideas and resulted in innovation in different disciplines and contexts and these ideas were transposed into a fashion context within the study. Some of the manufacturing mistakes identified in the archive garments included: sleeves sewn in the wrong way, incorrect stitch tension, using patterns that were unsuitable for a design, cutting fabric without making sure pattern pieces were straight, using the wrong interfacing or no interfacing at all, etc. These findings informed the design and manufacture of a collection of contemporary garments by the student group. The documentation of this process provides an important reference point for garment creators to disrupt conventional approaches to fashion design and technology and supports the development of innovative skills. These can be utilised to create new and novel clothing designs with which to enrich the global fashion industry.

Claire Evans

Senior Lecturer, Department of Fashion and Textiles, University of Huddersfield

Exploring grainline tilt through virtual garments wearer trials

My research and teaching currently focuses on garment production, alongside the 2D and 3D virtual realisation of fashion garments. Having worked in academic for many years I am now, alongside my fulltime role, studying for a PhD exploring viable grainline deviation for effectively repurposing jersey fashion surplus.

Day 2 playlist

View presentations and videos from day 2 of the Woven in Practice conference