Centre for Engineering Materials (CEM)

Welcome

Material research and engineering activity at the University of Huddersfield is spread over all seven schools and more than 12 research institutes and groups. The University has invested more than £5M in the development of the materials-related areas and will continue with at least this level of investment over the next five years. More than 150 university members are involved in the activity of the materials.

More details about materials research can be found at the associated Institutes, Centres, and Groups and associated staff pages.

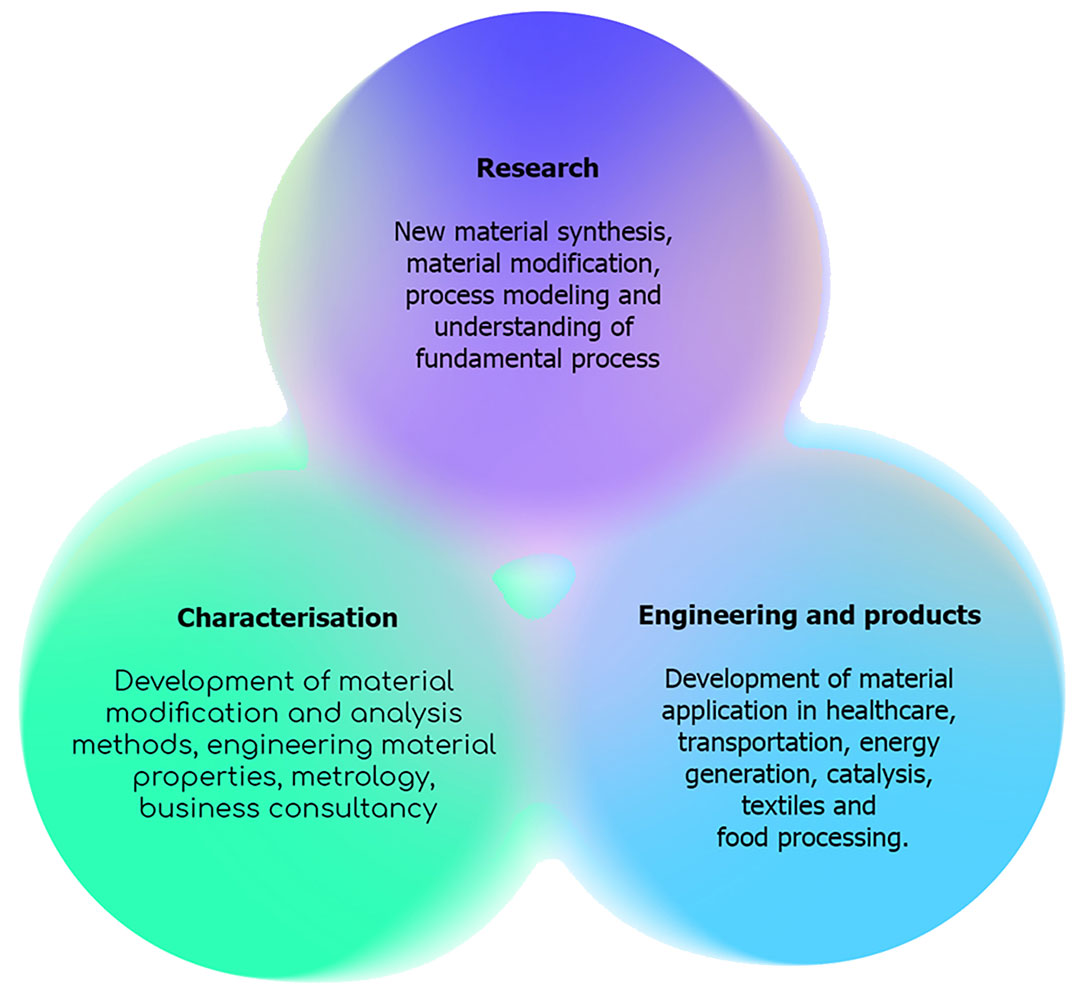

Materials activity can be schematically envisaged as the following diagram:

Find out more about Materials Research

Associated staff

Browse the staff members involved with Materials Research at the University of Huddersfield

Associated groups

Browse the Institutes, Centres and Research Groups associated with Materials Research.

Publications, Projects and Results

Take a look at our latest projects and results.

Teaching MSc Oil and Gas Engineering

Browse the teaching material for MSc Oil and Gas Engineering on our Coursefinder page

Facilities and Equipment

- Material Synthesis, Additive Manufacturing and Sample Preparation

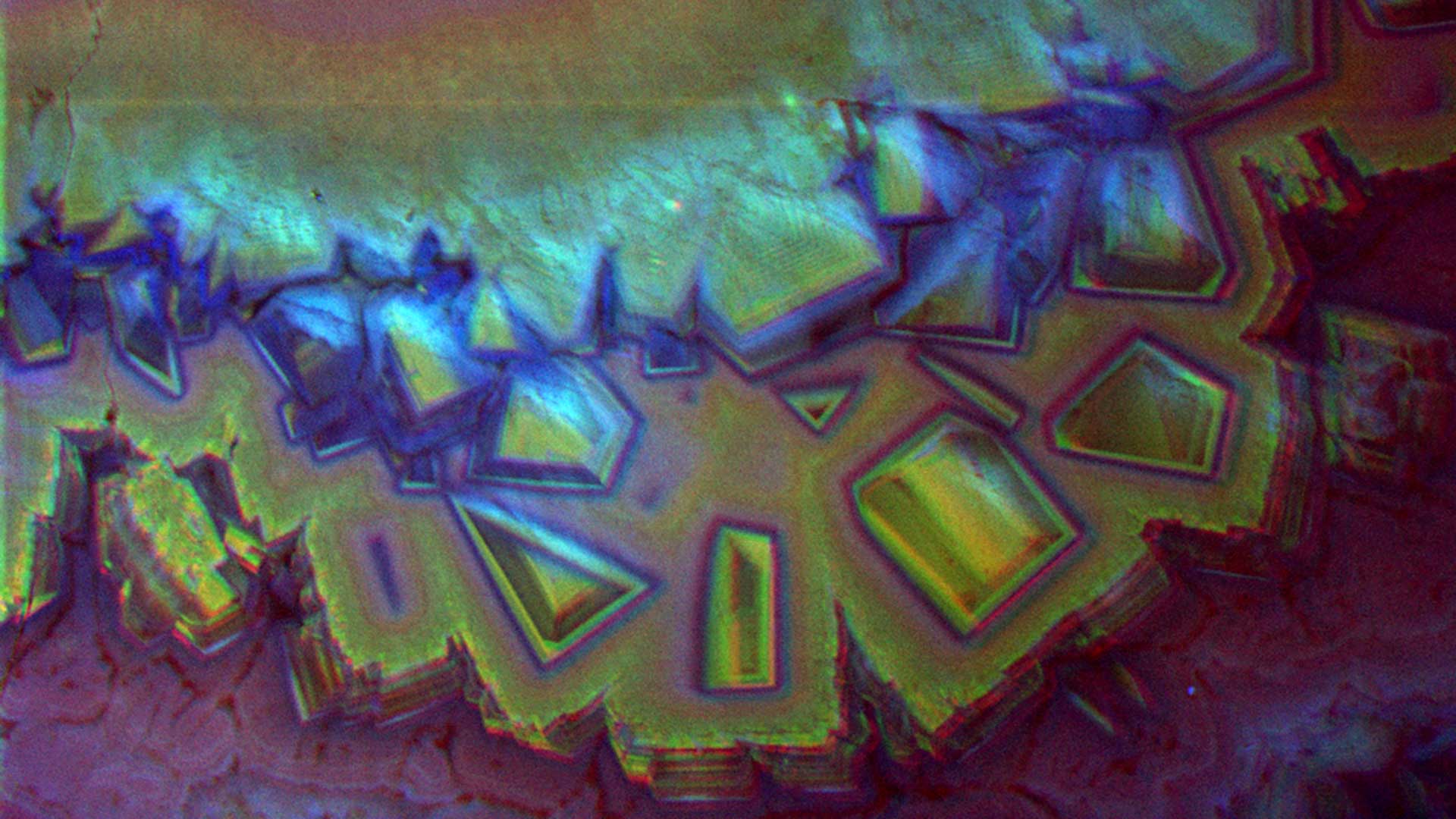

- Optical Microscopy and Spectroscopy

- Electron Microscopy, Spectroscopy and Analysis

- Ion Beam Accelerators, Modification and Analysis

- X-Ray Diffraction (Bruker lab)

- Engine and Turbocharger Test Beds

- Railway Roller Rigs

- Metrology and Precise Machining

Contact Us

If you would like to know more about our areas of expertise or wish to discuss research opportunities with Materials Research then please contact our Research Administration team:

Leader: Dr Vladimir Vishnyakov

Research Office

Computing and Engineering

University of Huddersfield

Queensgate

Huddersfield

HD1 3DH

Tel: 01484 473087