External Relationships

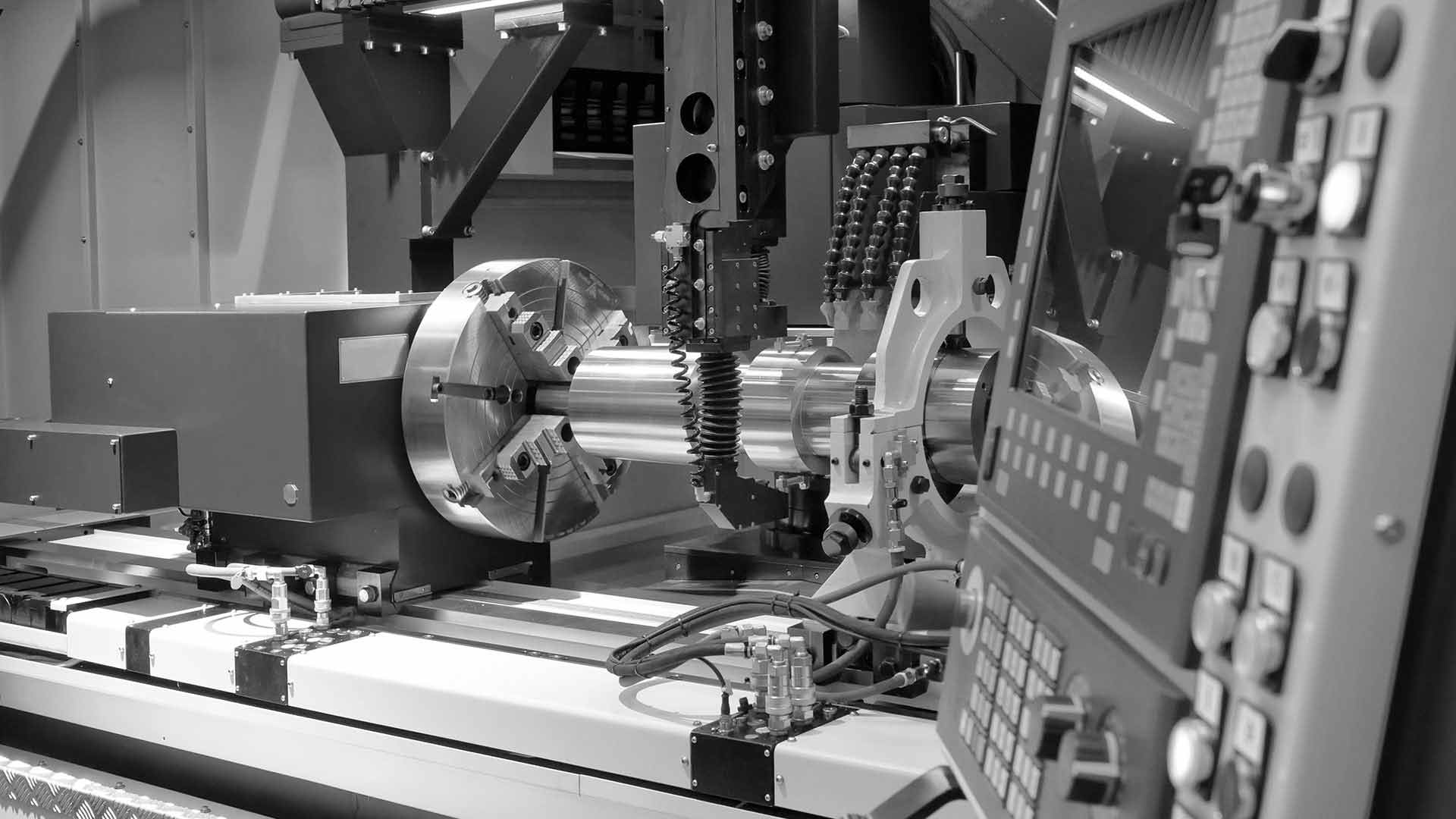

CPT supports the UK manufacturing industry by collaborating with key private and public organisations to deliver innovative solutions to long-term challenges. We work with companies in a variety of sectors including aerospace, automotive, biotech, instrument manufacturers and machine tool manufacturers.

CPT Partners

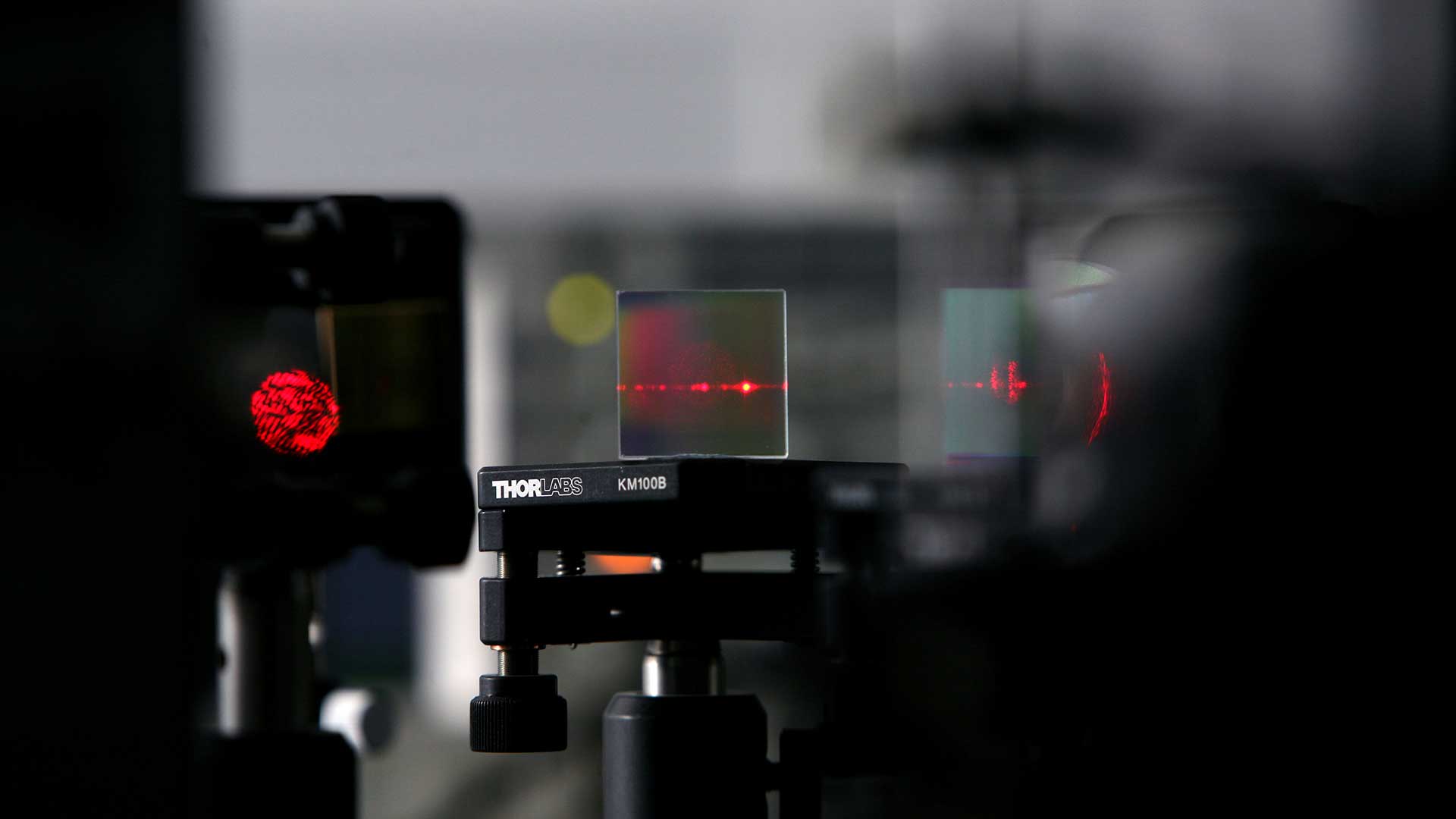

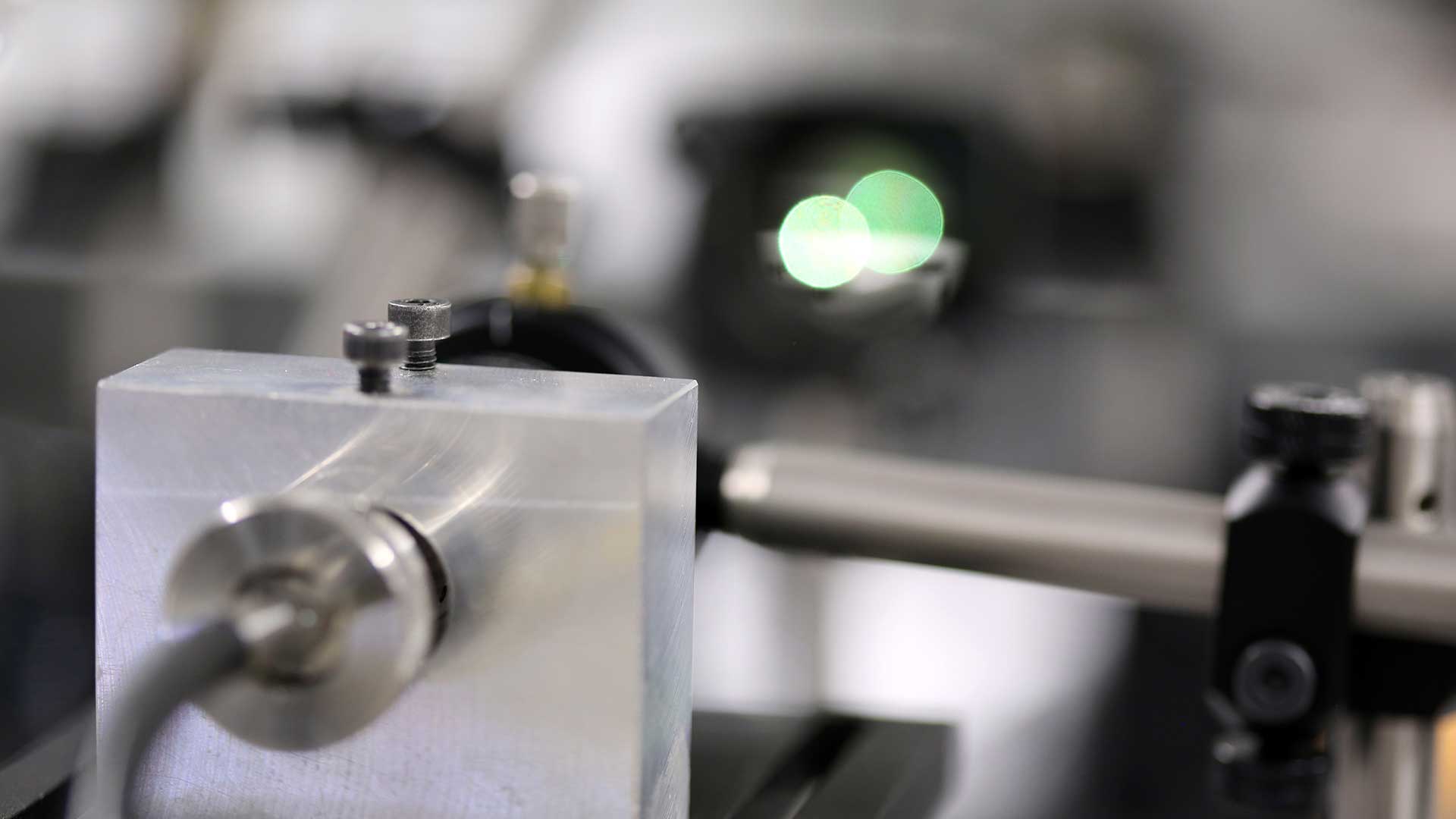

Our EPSRC Centre for Innovative Manufacturing in Advanced Metrology brings together a consortium of leading research and development organisations and global companies: Asquith Butler, CIP, Cummins Turbo Technologies, David Brown, MTA, MTT, NPL, Renishaw, Rolls-Royc, STFC and Zeiss. The partners are world-leaders in their fields and bring expertise, knowledge and resources to ensure that the research and projects will benefit the metrology and precision engineering sectors and ultimately lead to more efficient and accurate manufacturing processes.

Our track record of research and international expertise has been recognised by NPL (National Physical Laboratory) who signed a Memorandum of Understanding with the University providing a framework for collaborative research and business collaboration in the field of engineering measurement. As a result of this relationship and the expertise within CPT, NPL chose to open a Measurement Services Laboratory on campus, the only laboratory outside of its London base and the first of its kind of any university in the UK. CPT is part of NPL’s National Product Verification Programme which encourages and supports the adoption of measurement best practice.

Regional CPT work

Our work is strategically important for large national companies within precision engineering but it is also important for smaller regional companies. The local manufacturing sector is the third largest in Great Britain, employing 20% of the local population with advanced manufacturing representing the highest growth potential within manufacturing (Local Economic Assessment Report 2010/2011).

The Centre led a European Regional Development Fund (ERDF) Precision Technologies Centres of Industrial Collaboration project and is currently a partner in another ERDF project, Nanofactory. These projects, which work exclusively with regional SMEs, ensure that the University’s research and development expertise is being translated directly to industry and is bringing business benefits by accelerating innovation and creating commercial opportunities.

International links

At an international level we are recognised for CPT's metrology expertise and we work closely with the US and German national measurement institutes and collaborate with a number of Chinese and European universities including Beijing University, Tsinghua University, Fraunhofer institutes, Tampere University of Technology and Katholieke Universiteit Leuven.

Collaborative relationships

This multi-disciplinary team of over 40 research staff and students includes engineering scientists, physicists, mechanical and electrical engineers, mathematicians and computer software developers, ensuring a high level of innovation and collaboration from researchers who deliver excellence in learning and research. As a result, our researchers apply their research into different sectors and disciplines leading to collaboration into areas not commonly linked to precision engineering including skin science, forensics, implants and archaeology.

CPT has two industrially sponsored Chairs: the Taylor Hobson Chair in Surface Metrology held by Professor Paul Scott and the CHMTI-PTG Chair in Machine Tool Technology held by Professor Alan Myers.

We collaborate closely with the High Value Manufacturing Catapult, which includes the Advanced Manufacturing Research Centre (AMRC), the Manufacturing Technology Centre (MTC) and the Centre for Process Innovation (CPI), and we are a member of their metrology forum. We also work closely with the Universities of Bath, Cranfield and Leeds to deliver collaborative research projects.