Testing facilities at the IRR

The IRR provides specialist research in the fields of railway engineering and railway safety. Its core capabilities lie in the science and engineering practice of providing and maintaining a safe and economically optimised interface between vehicles and track. Computer simulation tools are developed and used and supported by practical tests in the IRR laboratories or on track. This expertise has been used to improve the design, operation and maintenance of railway vehicles and infrastructure in partnership with railway industry stakeholders and academic collaborators.

In 2015 the IRR commissioned its custom-designed adhesion and rolling contact laboratory dynamics rig ‘HAROLD’. It is the only full-size roller rig in the UK and the only one with its particular capabilities in Europe. It allows railway vehicles to be tested in the laboratory at speeds of up to 225kph, therefore providing an important National capability for the dynamic characterisation of bogies and for evaluating novel and innovative designs.

At the start of 2019, the Centre of Excellence in Rolling Stock (CERS) was officially launched at the IRR. It will share in the £90 million of funding, distributed among three Centres of Excellence, that has been procured from the Government and from the private industry by the UK Rail Research and Innovation Network (UKRRIN). As part of the investment in IRR to set up the Centre of Excellence 2 major new research facilities have been constructed:

- A £3.5M High-Speed Pantograph Testing rig which will provide a unique full-scale pantograph dynamic test rig with hardware-in-the-loop (HiL) facility for determination of dynamic interaction forces. Typical applications include the development and assessment of new pantograph designs, the optimisation of pantograph suspension systems and the development of novel mechatronic solutions.

- A £1.2M Train Hi-fidelity On-board Motion Simulator (THOMoS) which is a motion platform based laboratory simulator capable of reproducing the on-board motions and sensations. This will be used to carry out research into passenger comfort and the effect of various novel vehicle design

HAROLD

Full-Scale Bogie Rolling Contact, Adhesion and Braking Rig

PANTHER

Full-Scale High-Performance Test Bench for Pantograph and Catenary Research and Technology Development

THOMoS

Train Hi-fidelity Motion Simulator

Smart Maintenance Lab

Find out more about our Rolling Stock Maintenance Robotics Lab is a mini ‘depot of the future’, for research into the use of robotics for train maintenance.

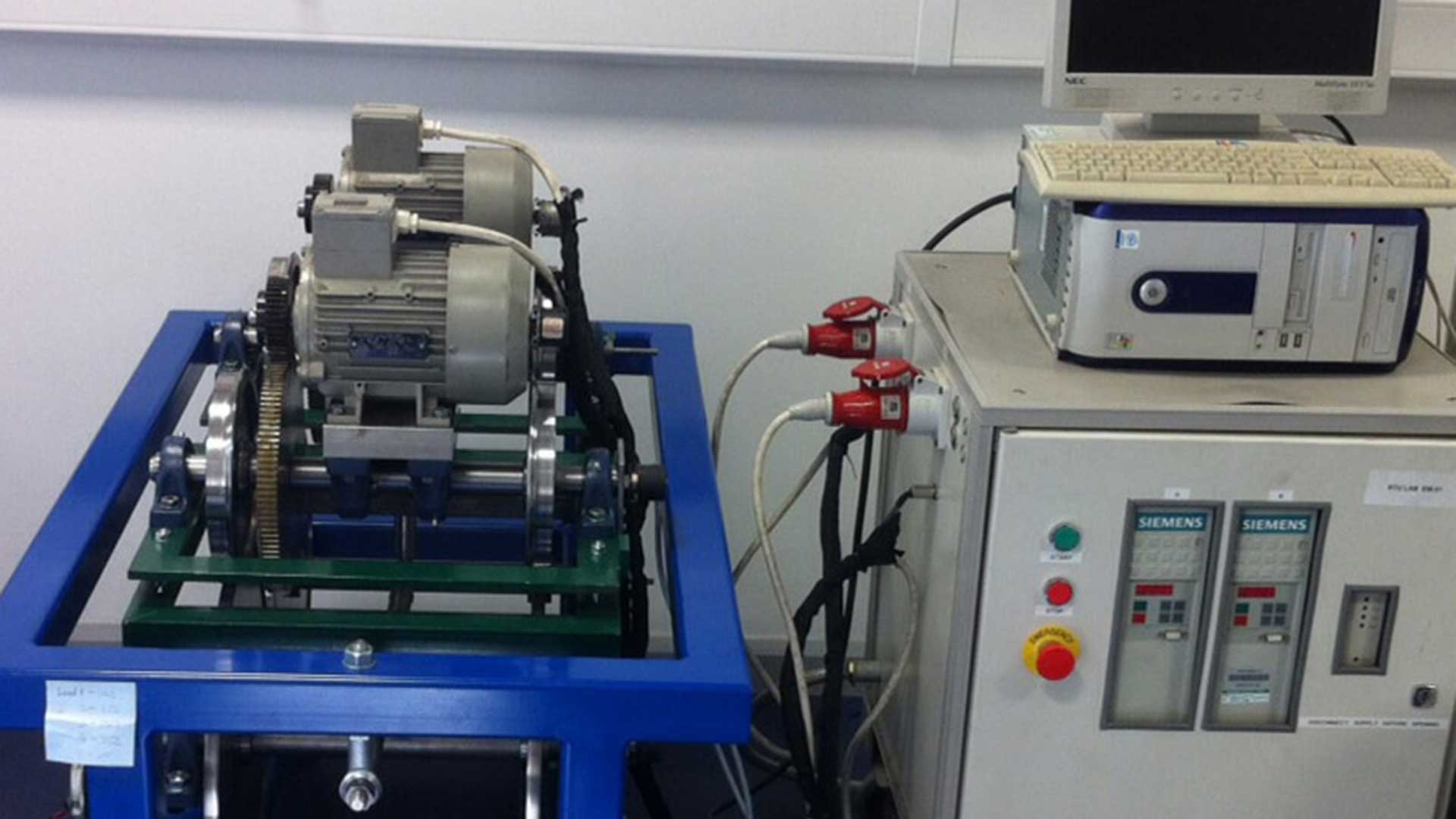

Scaled laboratory test rigs

The IRRs Scaled laboratory test rigs include a 5th scale roller rig (1 bogie or single axle) and twin disk roller rig

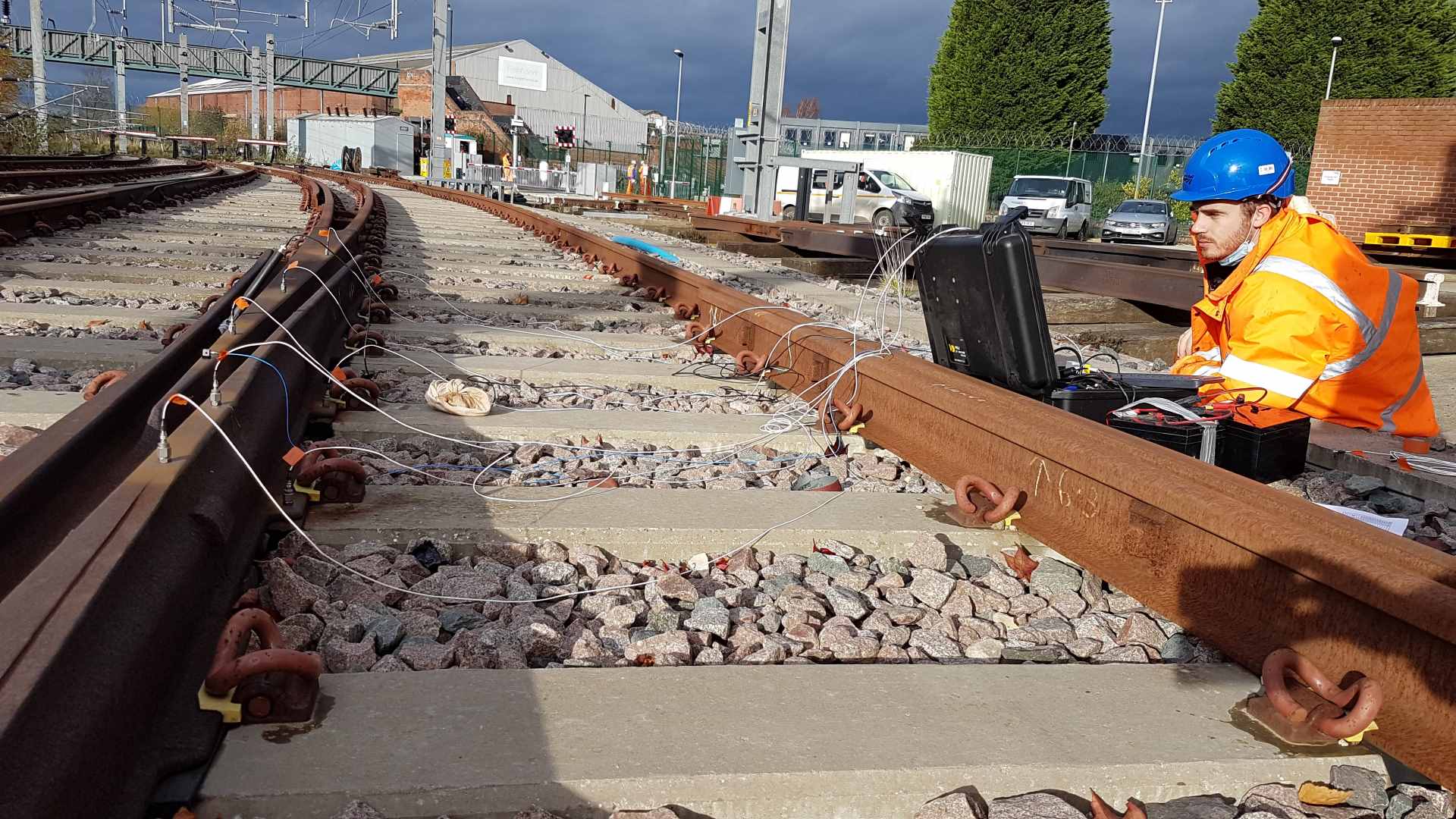

Track and vehicle measuring equipment

The IRR has various track and vehicle measuring equipment.

High Performance Computing (HPC) system

The IRRs high performance computing cluster is the engine behind the Institute’s developing expertise in data analytics and natural language processing.